Image by Manfred Richter from Pixabay. All product names, logos, and brands used in this post are property of their respective owners.

If you are looking to upgrade your long board (skateboard), I would argue that bearings make the biggest difference. Just like replacing a magnetic disk in your computer with a solid state drive (SSD), new bearings can breathe life into your board. There are many great options for longboard (or skateboard) bearings - generally speaking, the more you are willing to spend, the “better” the bearing.

When money is no object, spring for a set of Bones Ceramic REDS and call it good. But what about value? I set out to examine the performance of 3 popular, lower cost skate bearing options:

- Bones Super REDS - $31.95 (SKU BSACSR88 / UPC 845584018610)

- *Mini Logo “2” - $10.50 (SKU BSACML288 / UPC 845584042240)

- Bones REDS - $18.95 (SKU BSACBR88EC / UPC 854175000279)

*Note: I tested Mini Logo "2" bearings (the earlier generation). Mini Logo Series 3 are an improved version and have been available since ~August 2018.

Short answer, based on performance alone, Mini Logo bearings appear to deliver the best value BUT if you are willing to spend $20 (3x) more, Bones Super REDS offer the best performance. Bones REDS bearings performed identically to Mini Logo bearings, but REDS cost about $8 more.

Results

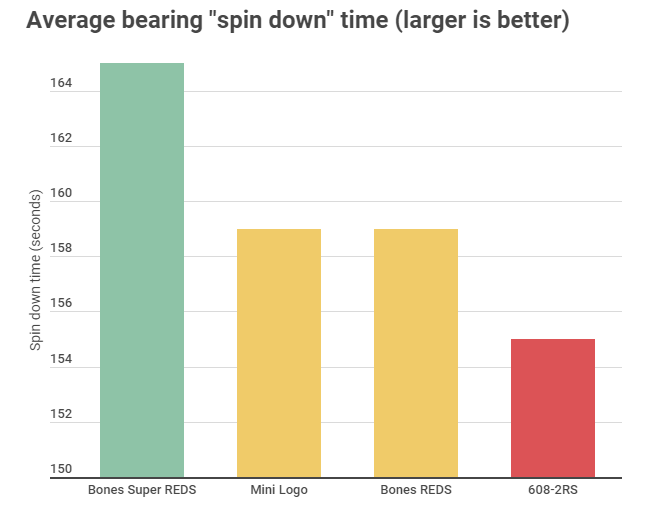

I’ve ranked the bearings by average “spin down time” in seconds - that is, the time it took the bearing to come to a complete stop (under load - 35 lbs or 15.9 kg) after being “spun up” for 20 seconds using constant air pressure. The longer the spin down time, the better. I averaged the result over 5 trials (and added a coefficient of variation as a sanity check).

I included a generic ABEC-9 bearing (model 608-2RS) in the graph as an additional data point. The name brand bearings all performed better than the generic bearing.

| Bearing | T1 | T2 | T3 | T4 | T5 | Avg | CV |

|---|---|---|---|---|---|---|---|

| Bones Super REDS | 157 | 163 | 166 | 175 | 165 | 165 | 4% |

| Mini Logo "2" | 160 | 164 | 156 | 155 | 162 | 159 | 2% |

| Bones REDS | 155 | 160 | 152 | 161 | 168 | 159 | 3% |

With this experiment, the spin down times are close (only a 4% difference between each model and 6% difference between the best and worst). I honestly expected a larger difference, but this could be an experimental design issue.

You can download my data as CSV if you desire.

Also note, this test is based on “out of the box” performance. These results may differ as bearings are broken in, speed cream breaks down, and components wear out. I suspect the higher cost bearings may last longer but I did not evaluate that.

The experiment

My inspiration for this comparison and experiment came exclusively from JohnnyQ90’s work in Steel VS Full Ceramic Bearings (Friction Test). Using air pressure to drive the bearing is genius; when I started thinking about this initially, I struggled to think of a consistent way to accelerate the load. Thank you for that one JohnnyQ90!

I wanted to improve the accuracy of the experiment (in the context of longboarding) by testing bearings under load. I figure that 35 lbs (15.9 kg) x 4 wheels is equivalent to the load of a 140 lb (64 kg) skater (manuals excluded). As it turns out, Olympic weight plates (barbells) have a 2" diameter hole. That is about 51 mm, which is close to a common skateboard wheel diameter. I mounted an old skate board wheel in the plate’s hole, attached a blower cage to the plate, inserted the bearings, and placed the assembly on an old skateboard truck I mounted to a nogging in my garage.

Procedure

- Mount 2 x test bearings in the wheel/weight apparatus, then install onto the truck

- Ensure wheel/weight apparatus is balanced (stays at rest)

- Power on the blower (simultaneously starting a stopwatch), and apply air pressure to the blower wheel (1 inch/2.5 cm away) for 20 seconds (this typically accelerates the wheel to 80-90 rpm)

- At 20 seconds, power off the blower and create a split on the stopwatch

- Wait (2-3 minutes) while the wheel assembly spins down to a complete stop

- When the wheel comes to rest, stop the watch and record the duration of the split

- Repeat 5 times for each bearing model

Spin up (20 seconds) and spin down

Here is a video to illustrate the test process. No audio - I will spare you the sound of the blower.

Closing thoughts

I am on the fence about the results of my testing; there appears to be a sensible pattern but additional testing (more iterations) is needed in my opinion. There are also angular and linear velocities which I opted to ignore during my testing.

Still, if you are looking for a low cost, high value bearing upgrade, Mini Logo looks like a good bet. These bearings will outperform generic ABEC (ABEC-7, ABEC-9, etc.) bearings that are included with many boards.

Use this data and experiment as you will - with some improvements, it could make a neat Science Fair project!